Main Parts of Control Valve

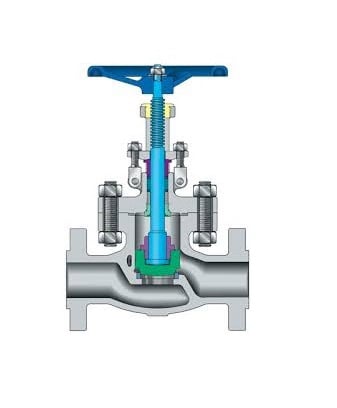

Valve Body

The casing that holds the internal parts.

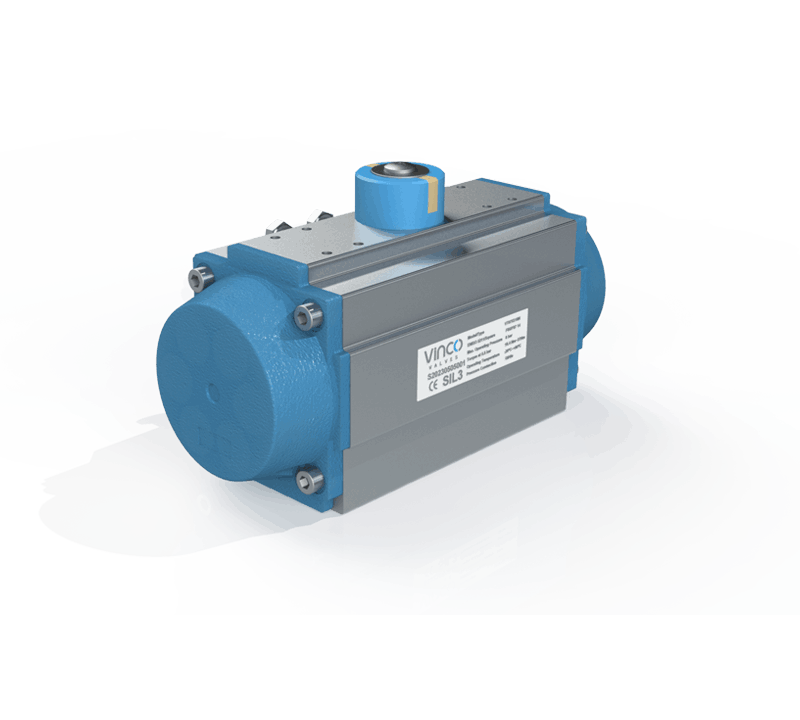

Actuator

The device that moves the valve plug/disc (can be pneumatic, hydraulic, or electric).

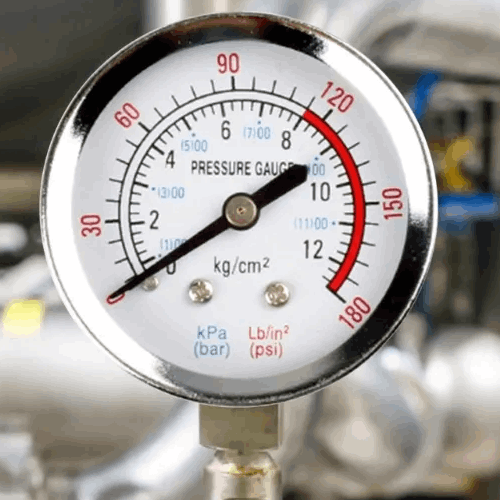

Positioner

Ensures the valve opens to the exact position according to the control signal.

Plug/Disc

Controls the flow by moving up/down or rotating.