Common Types of Pipe Fittings

Elbow

Used to change the direction of flow.

Common angles: 45°, 90°, 180°.

Available as short-radius and long-radius types.

Tee

Has one inlet and two outlets (T-shape).

Used to branch the pipeline.

Types: Equal Tee (all openings same size), Reducing Tee (one outlet smaller).

Reducer

Connects pipes of different diameters.

Concentric Reducer: Centerlines of pipes are the same.

Eccentric Reducer: Centerlines are offset (to prevent air pockets in horizontal pipes).

Coupling

Used to join two pipes together.

Types: Full Coupling, Half Coupling, Reducing Coupling.

Union

Similar to a coupling but allows quick disconnection (maintenance-friendly).

Cross (Four-way fitting)

Has one inlet and three outlets (like a “+”).

Used in fire-fighting systems, sprinklers, and irrigation.

Cap / Plug

Used to close or terminate the end of a pipe.

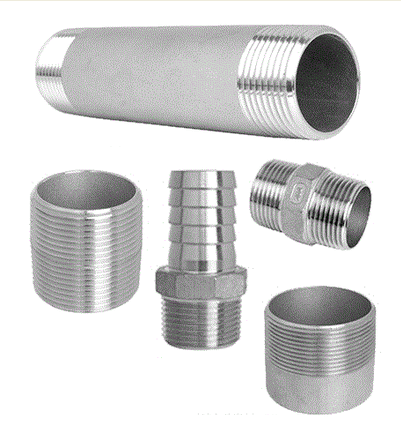

Nipple

Short length of pipe with male threads on both ends.

Used for small-length connections.

Bend

Like an elbow but has a larger radius for smooth flow (less pressure drop).

Valve (Technically a fitting)

Controls the flow of liquid/gas.

Types: Gate Valve, Ball Valve, Globe Valve, Butterfly Valve, Check Valve.