Types of Gland Packing Material

Asbestos Packing

Made from asbestos fibers, sometimes impregnated with lubricants or graphite.

Good heat resistance, but rarely used now because asbestos is hazardous.

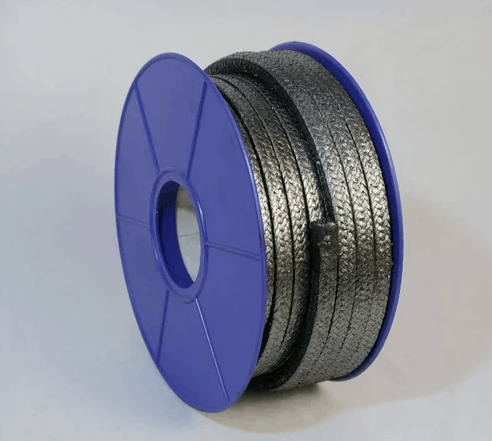

Graphite Packing

Made from flexible or braided graphite.

Excellent heat resistance (up to 450–650 °C).

Chemically resistant → used in high-temperature, high-pressure steam, and chemical services.

PTFE (Teflon) Packing

Made from Polytetrafluoroethylene (PTFE).

Excellent chemical resistance and low friction.

Suitable for corrosive fluids but not for very high temperatures.

Carbon Fiber Packing

Braided carbon fiber, sometimes with graphite.

High strength, good thermal conductivity, and chemical resistance.

Used in pumps and valves for chemicals, steam, and hot water.

Metallic Packing

Made from soft metals like lead, aluminum, or copper.

Can withstand very high pressure and temperature.

Rarely used today, replaced by graphite and advanced composites.

Non-Asbestos Fiber Packing

Made from synthetic fibers (aramid, acrylic, Kevlar®) with lubricants.

Environmentally safe alternative to asbestos.

Used in general service applications.